|

|

Post by Penguin45 on Aug 19, 2015 22:38:51 GMT

I think that that's a sensible thing to do, Tony. Looks pretty good. I might ask Mother to make up a little grey cloth tube to go over the paddding and then no-one will know that it's there.

Chris.

|

|

|

|

Post by dave1800 on Aug 20, 2015 1:10:12 GMT

Hi Tony

I hope you were not troubled by the recent typhoon? I see there is another maybe arriving at the end of the week.

Not just crab water pumps. Mine failed after 80,000 km and my neighbours after just 35,000 km on a Toyota SUV based on the Hilux diesel. Similar symptoms leak one day not the next. Just a dribble but not worth risking. Quite cheap considering the complexity of the casting and easy to get to.

Regards

David

|

|

|

|

Post by tony on Aug 20, 2015 6:20:17 GMT

Yes, there was a typhoon that blowed down many trees here last Saturday. We survived as our garage is NOW an indoor place. On that Saturday afternoon we did come to our garage to take a look if something went wrong. Thanks to God. Everything was fine. They say there are another two coming this weekend, one of them is very sure to approach to us. From the begining of this year there was a shortage of water, now there is too much. Thank you for your concern, David. About the headrests, one of our customers gave us the two used headrests, probably europeans made. Father cut off some piece of the two matel of each headrest to make them shorter and could be connected to the house water pipe modified. I have to leave right now for work on a Camry AC conditioning system. And I will come back to take about another water pump of Toyota Vehicle. Many thanks. Regards Tony Hi Tony I hope you were not troubled by the recent typhoon? I see there is another maybe arriving at the end of the week. Not just crab water pumps. Mine failed after 80,000 km and my neighbours after just 35,000 km on a Toyota SUV based on the Hilux diesel. Similar symptoms leak one day not the next. Just a dribble but not worth risking. Quite cheap considering the complexity of the casting and easy to get to. Regards David |

|

|

|

Post by tony on Sept 5, 2015 6:01:50 GMT

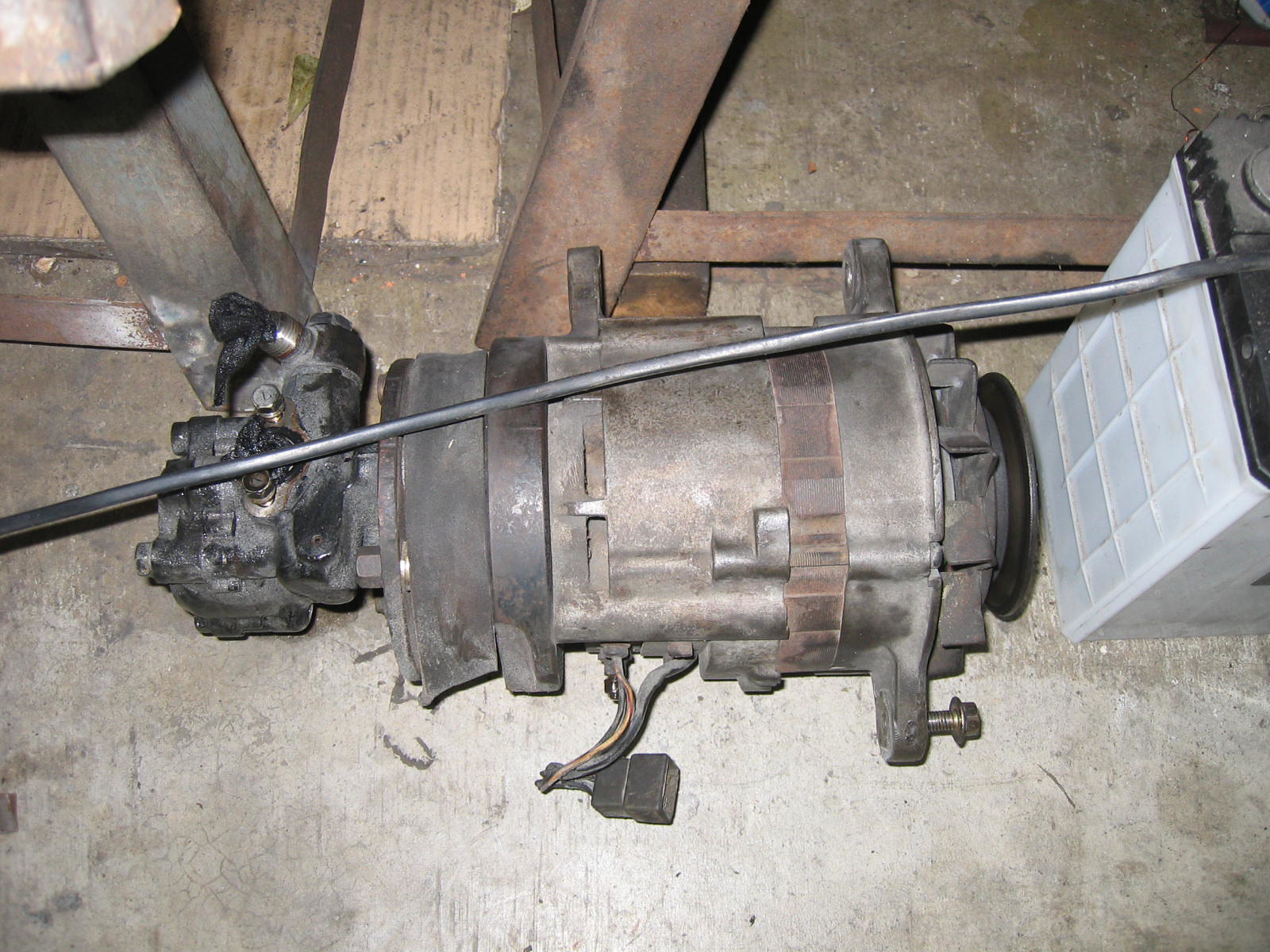

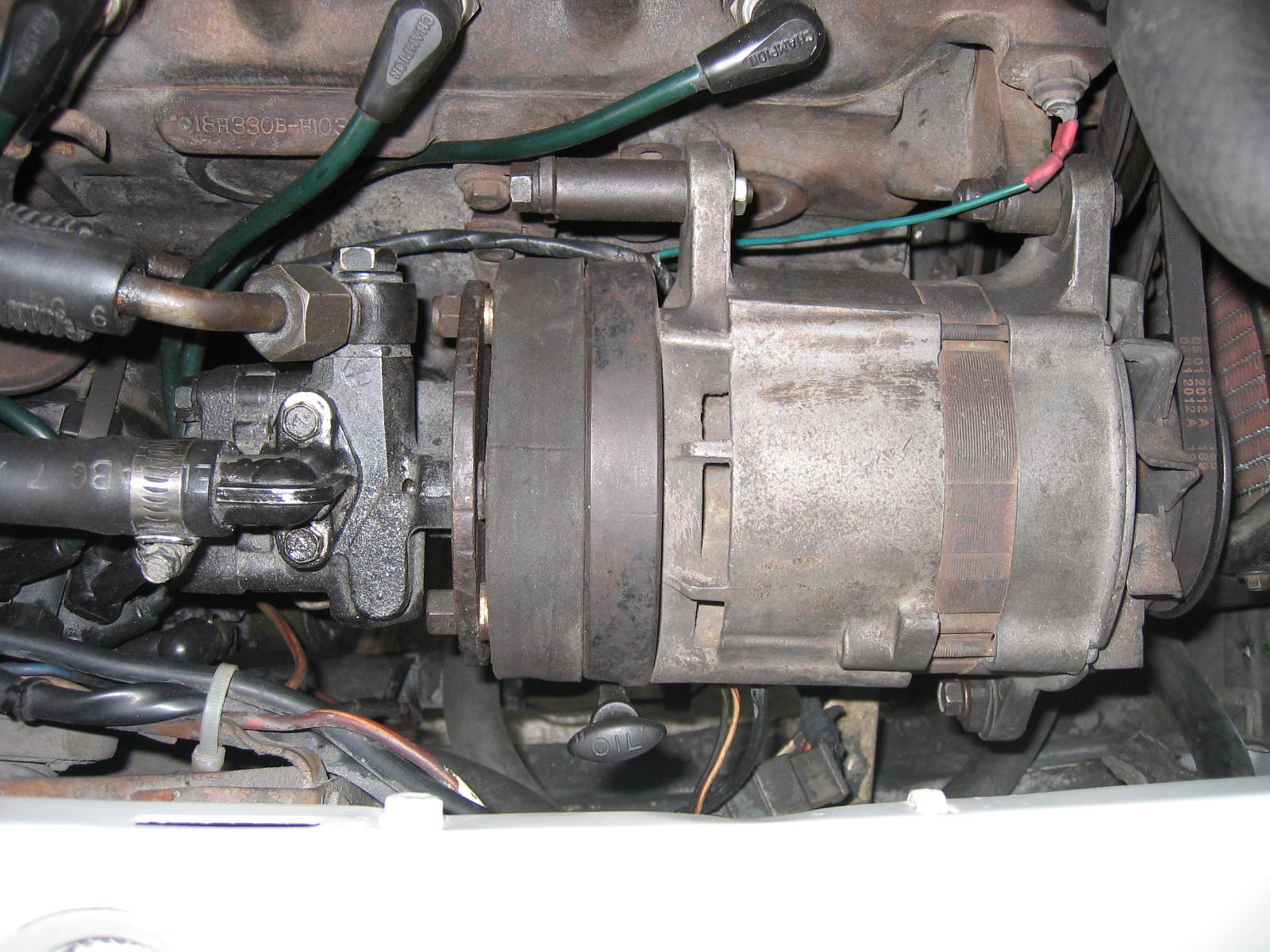

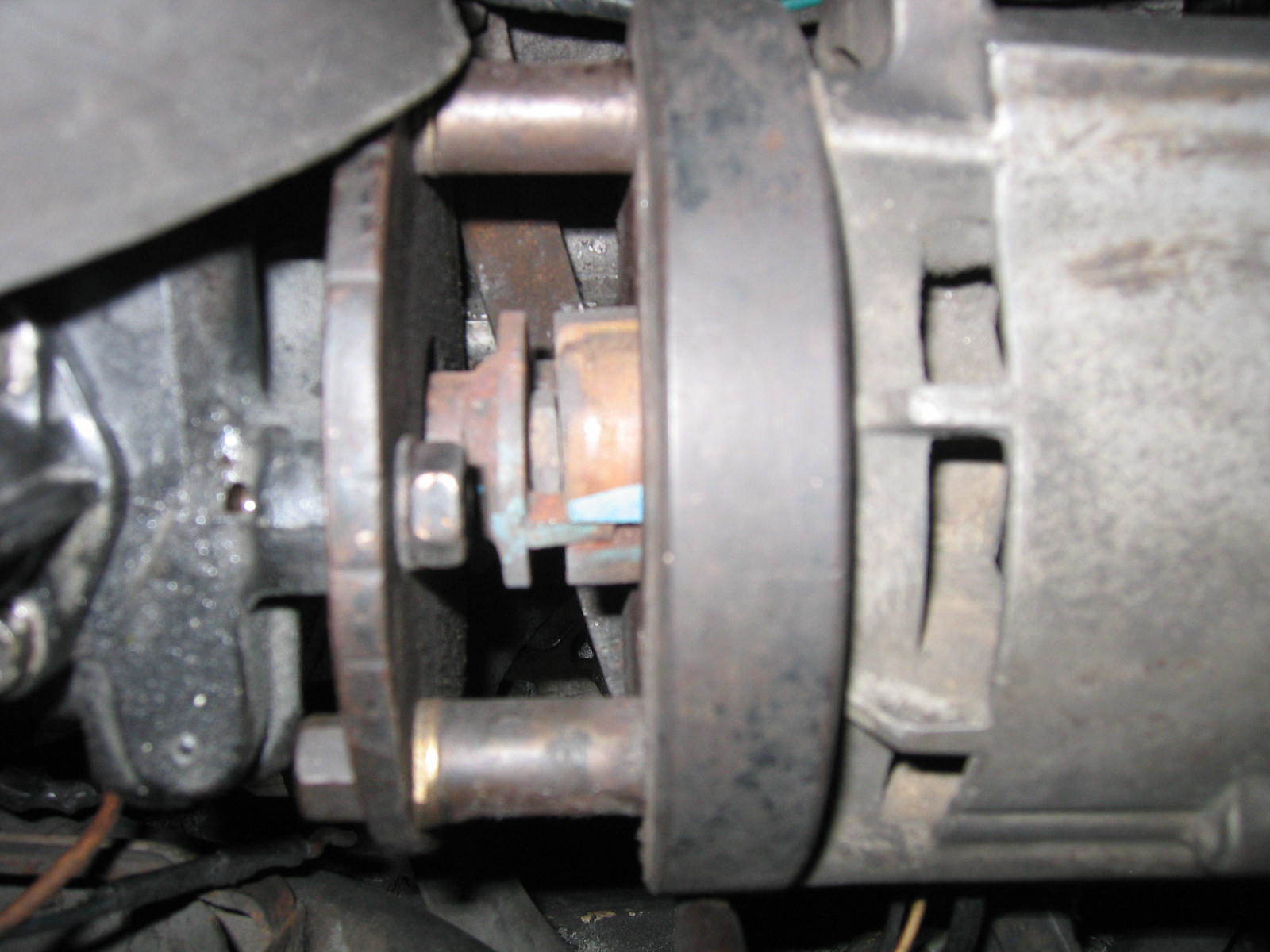

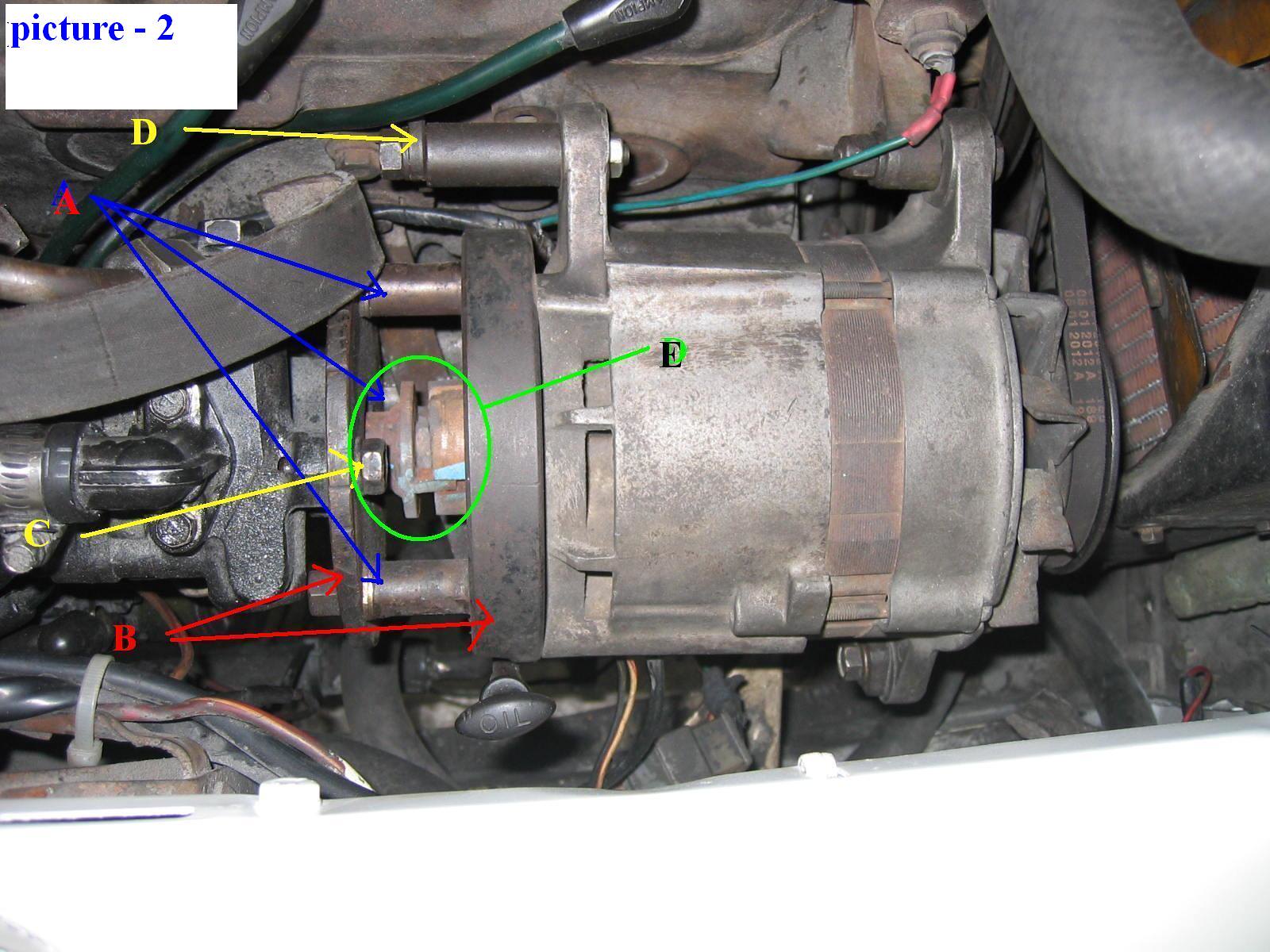

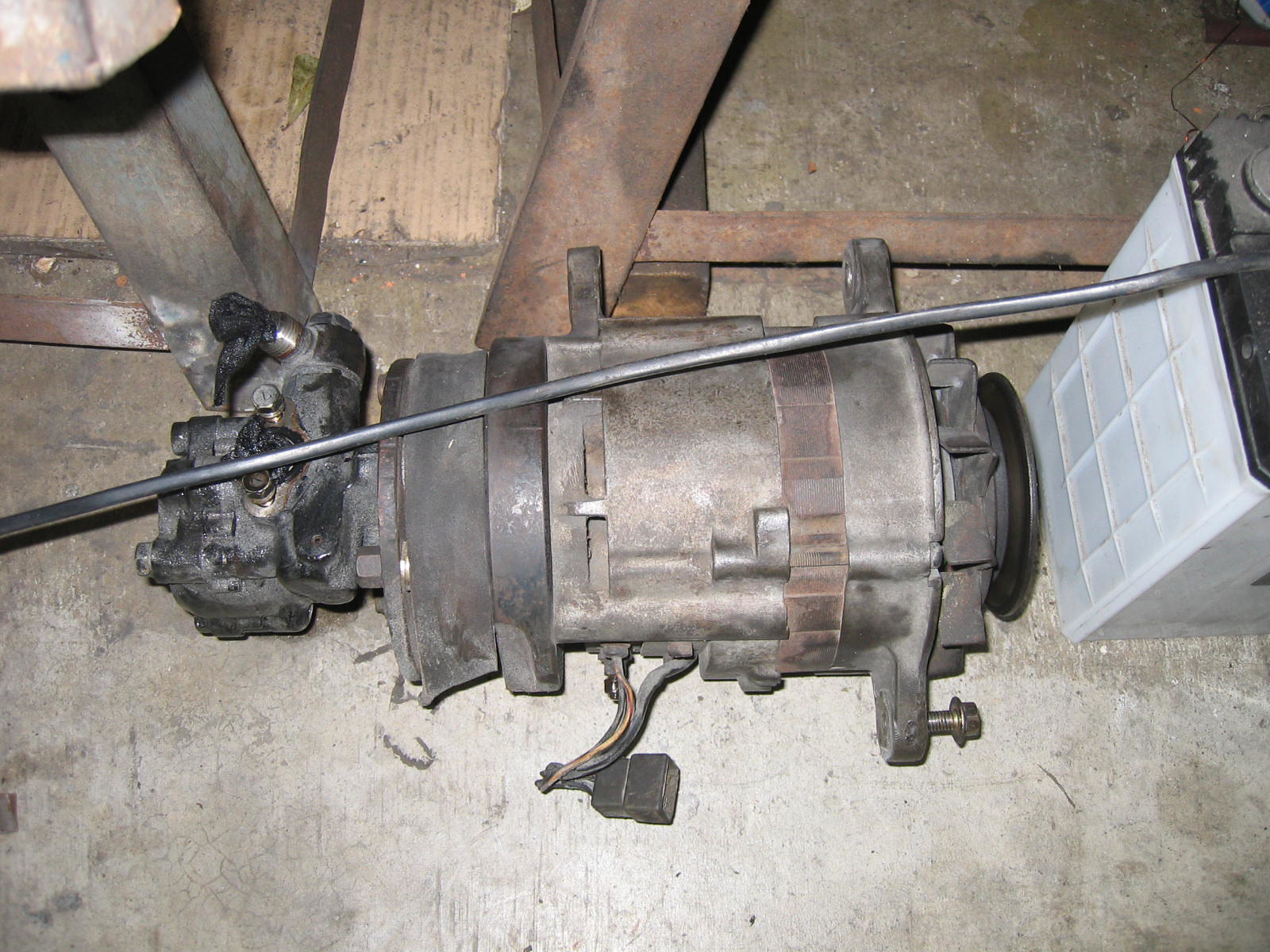

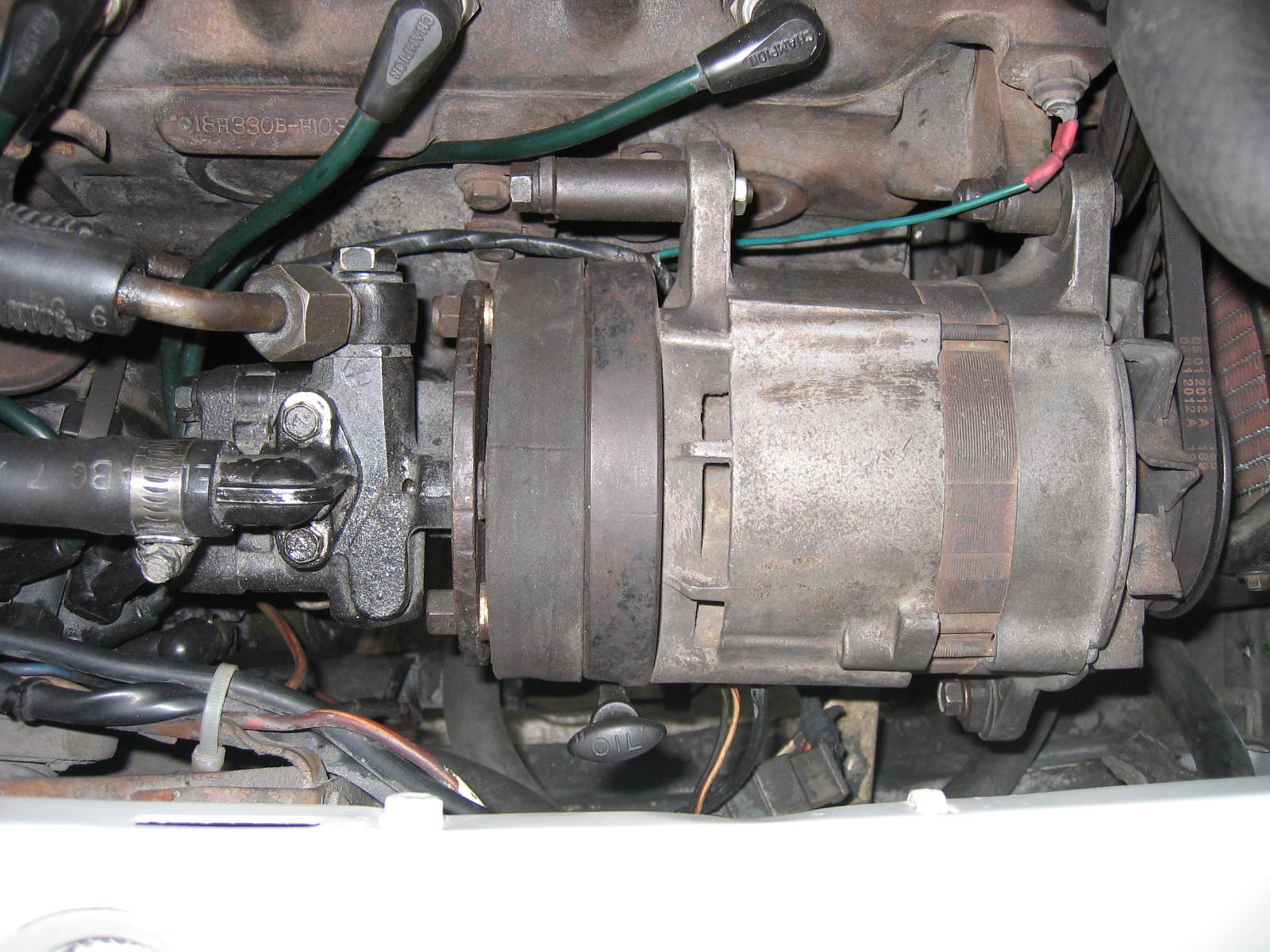

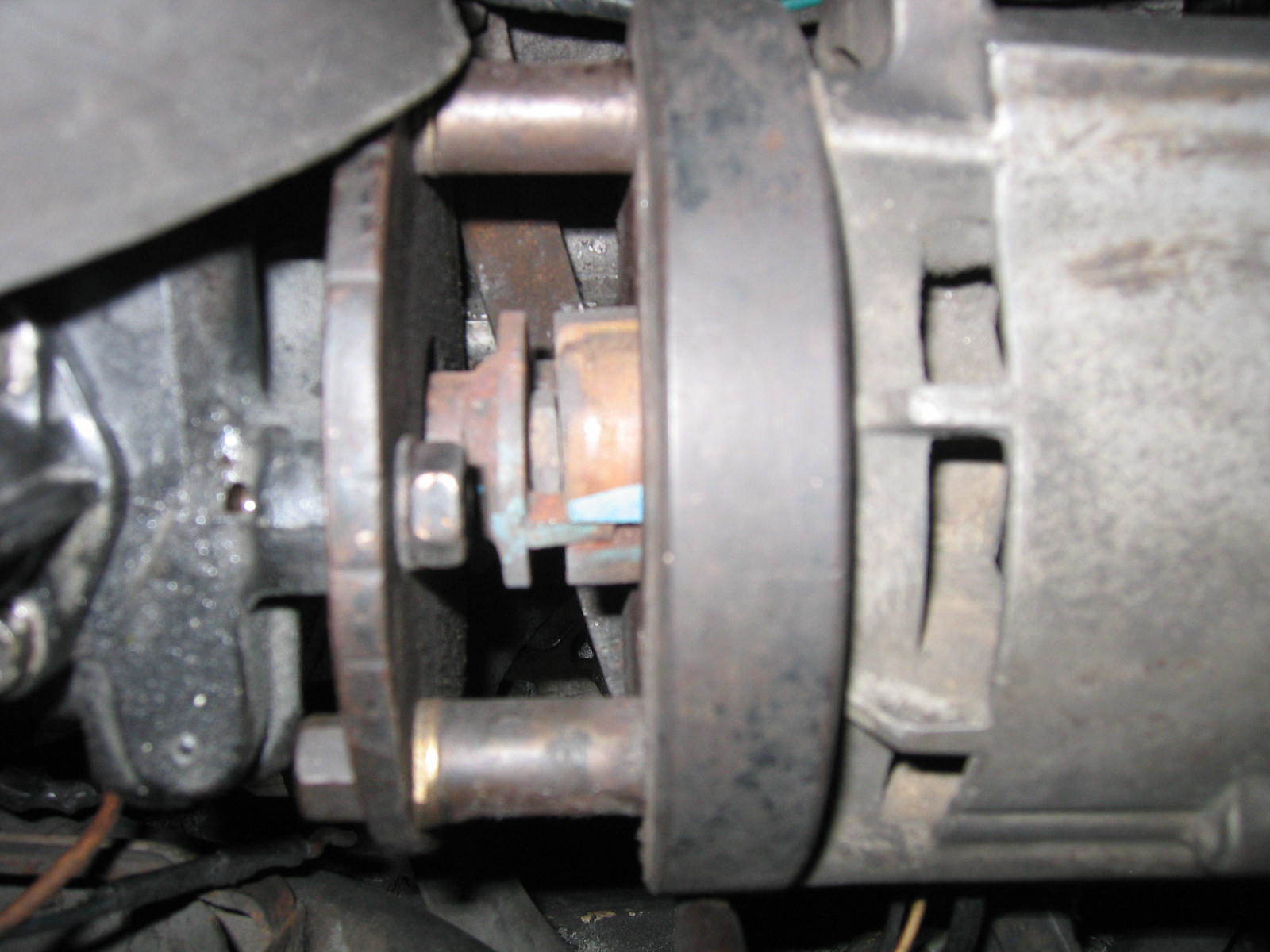

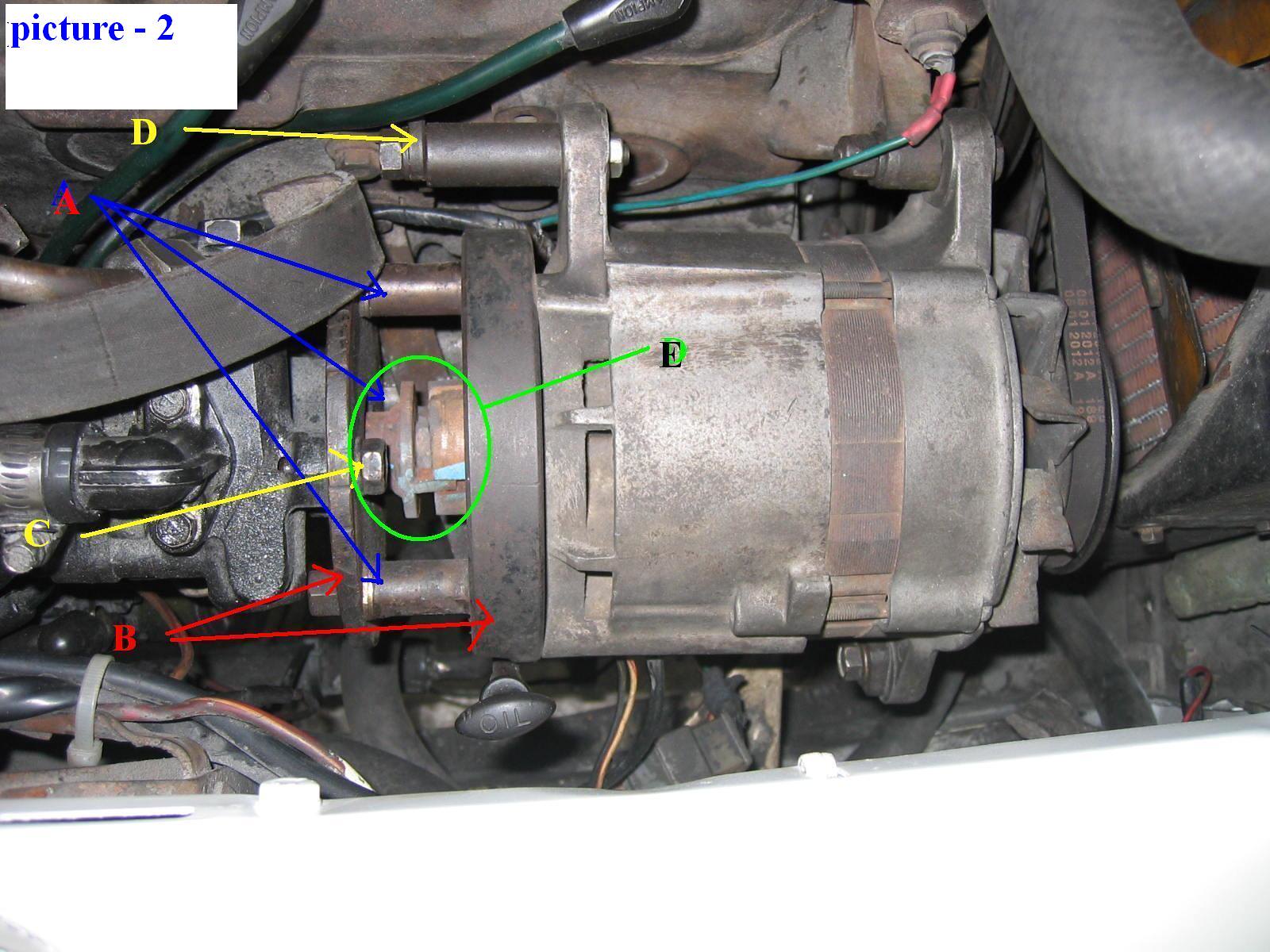

As asked by Al, alonel, I realized I had missed to upload some pictures here, which I did send to Anthony Wood last year after a mail from him. Al wants to know how to put generator and power pump together like we did. I add them here.   This generator is a Japanese Mazda Diesel style for van, which doesn't produce more power, I mean ampere, but it is still enough for our vehicle. The power pump came from a Japanese little car.  The connector created by father. Removal the cover, you can see the connector between the generator and power pump. See the below picture:  There are A, B, C, D and E. A and C: bolts, nuts B : two round plates: one thick, the other thin D : bolts, nuts and  E : a hand made special connector  This reliable evaporator assembly plus AC controller is very hard to find nowadays. I heard there is a mechanic who has collected some unusable ones to install on Mitsubishi Canter trucks. Regards Tony |

|

|

|

Post by tony on Sept 16, 2015 1:56:44 GMT

Our landcrab has equipped the power steering system since people here imported from UK. So the system is original, I mean that the power steering rack now is still original and the power pump has been changed. There is an adjustment to balance the power fluid pressures of the both sides of steering rack after doing the overhaul of steering rack. Doing the adjustment is not quite easy sometimes, but practice makes perfect.

Regards

Tony

|

|

|

|

Post by tony on Aug 26, 2017 5:15:40 GMT

A month ago, just in later July. There was a very strange sound coming from the rear of Morris while she moved backwards. At that time I thought it could be the cause of rear brake shoes. In fact, I was wrong to first diagnose. I had almost forgotten the problem of the so closed gap between the rear right wheel and the body frame. I still have the picture of the problem shown below:   Found the cause of the strange sound.    We used a 5th jack to support the vehicle, just for the safety while working under the vehicle. More than a month ago, I received an internet video showing a fall-down vehicle from a lifting machine that killed two techs immediately. I heard this kind of accident decades ago. As of the results, I have been very careful to do the lifting very slowly to make 100 % sure for the safety. I maintenant my lifting machines per month. Thanks to God because God has saved us twice.   We found the cause as we expected. |

|

|

|

Post by tony on Sept 21, 2017 3:20:08 GMT

|

|

|

|

Post by dave1800 on Sept 22, 2017 11:37:01 GMT

Hi Tony

Thanks for posting and also for recreating your blocked Photobucket pics, much appreciated.

Are the new bushes made from PTFE (Teflon)as I believe you used for the LH side a few years ago? Are you able to preload the bearing and are the LH ones working well?

regards

David

|

|

|

|

Post by tony on Sept 23, 2017 9:25:50 GMT

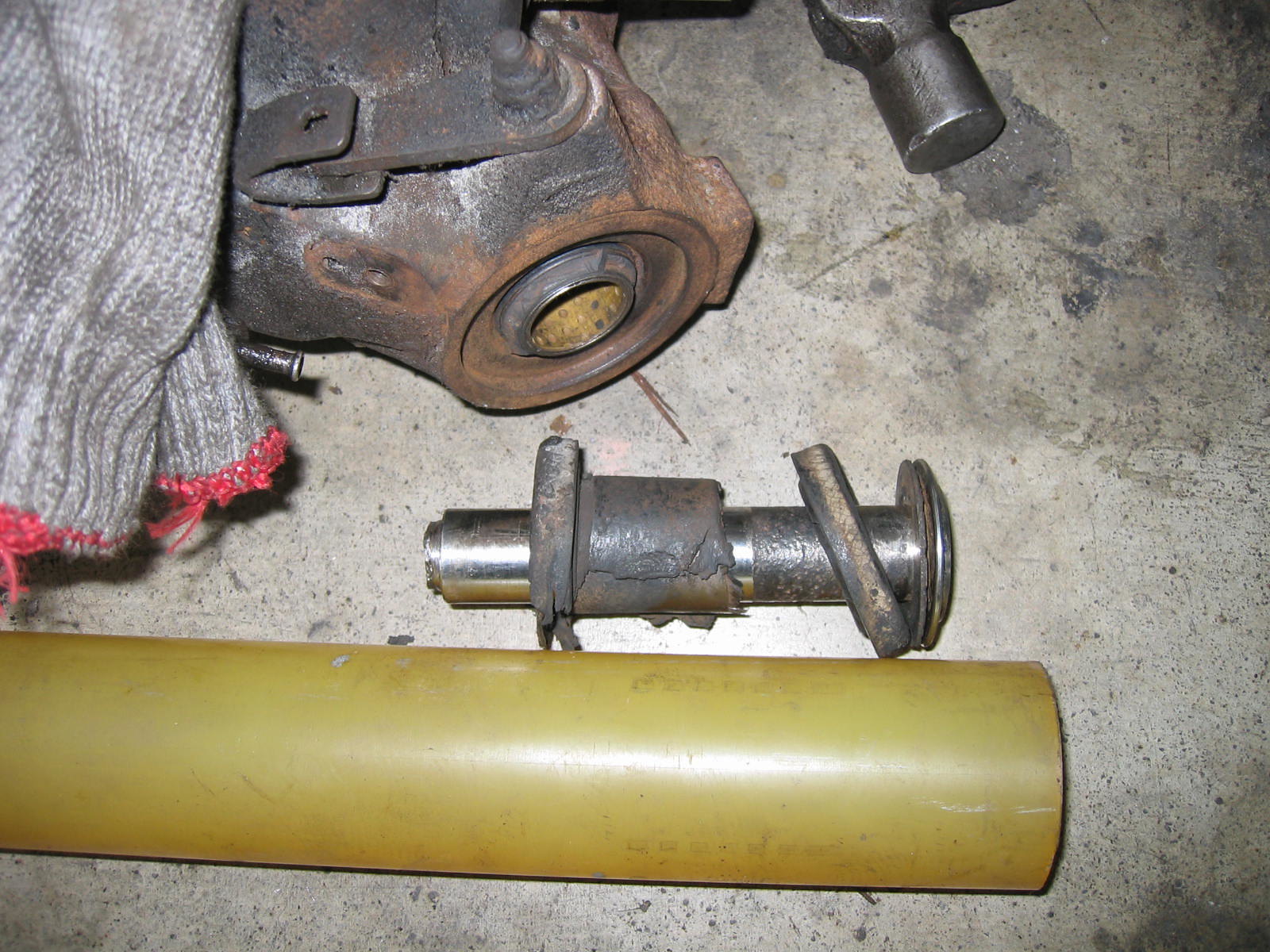

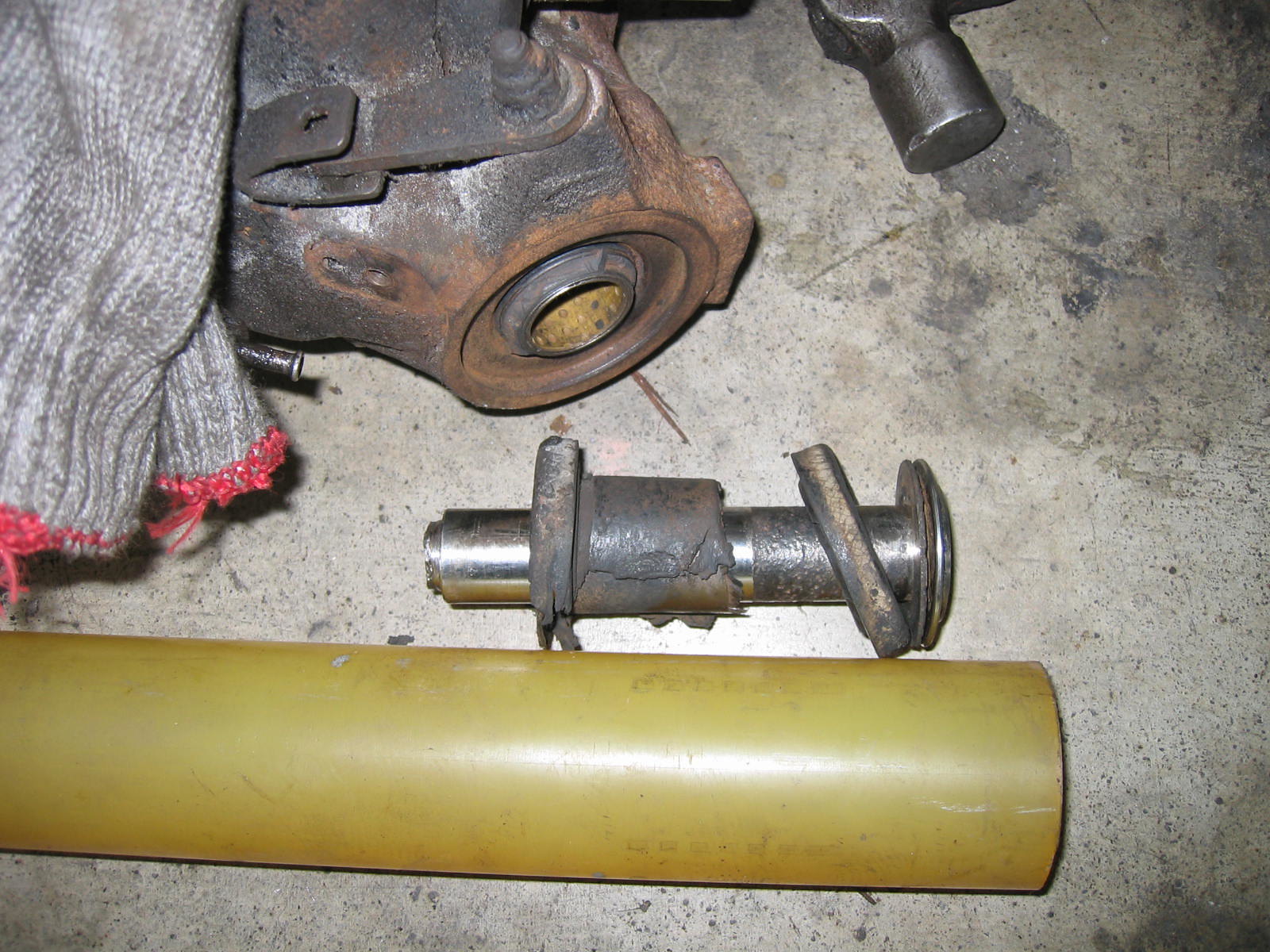

Hi David First of all, I am sorry about some unclear pictures of the bushes I uploaded here. I was unable to upload some of small size pictures here from the my account of Flickr.com. So I had to retake them again in front of the screen of the computer in order to meet the requirement of bigger size. The result is unclear pictures. The picture below is LH side we repaired by using the light yellow material and made the bushes in 2014. I believe it's called Teflon. It has been working fine since then. It's like the bushes by PowerFlex, a UK company. In 2014 I didn't have the chance to take any pictures of the bushes father went out to tell someone to create what he really wanted. He gave the person a guidance and stayed there and watched him make the correct size bushes he asked for. It's very clear that we just use the new Teflon bushes instead of the rubber made bushes. And we still use the rest of the parts left and put them back together as a whole "Slipflex DX" bearing assembly inside the arm. Of course, the size has to be correct, which is not very difficult for old mechanics like my father to do the job. He has used Teflon for Lexus 400, RR and others.  ![]()    I am very sorry again. The size of original pictures is very small and they are not very clear I took this time. Also sorry for being unable to take a whole new Teflon "Slipflex DX" bearing assembly because father installed them piece by piece into the arm. Regards Tony |

|

|

|

Post by dave1800 on Sept 25, 2017 0:56:11 GMT

Thanks Tony. Teflon is relatively easy to turn on a lathe and there were plenty small pieces available of Ebay last time I looked (it isn't cheap if you have to purchase a full length rod). I had a look at the Powerflex website and maybe their exhaust hangers could be used on crabs?

regards

David

|

|