|

|

Post by dave1800 on Oct 4, 2014 7:25:42 GMT

Tony, that's interesting. There is a reference in one of the LOCI magazines to a service that was/ is offered to replace these slipflex bearings with bronze or maybe brass I can't quite recall. But that would have required you to ship the arms back to the UK. If you have a chance I'm sure readers here would welcome more details of the teflon bearings and maybe a limited long term test? I guess I should have included rear suspension alignment in my earlier request for information as the slipflex can distort sufficiently for the rear tyre to touch the body and certainly upset the handling. Only Mk1 and rally cars used the roller bearings to my knowledge. Regards David View Attachment View AttachmentWe removed the worn out part --- called Slipflex DX bearing and rubber. This was different from my first thought. Father used teflon to create our own parts. |

|

|

|

Post by tony on Oct 4, 2014 8:56:06 GMT

David Father has done the same job on a RR, a Lexus LS400 and others when parts are not available or require to buy the part with arm that will cost a lot. Those were done at their front suspension lower arms. It seems quite doing right at their angle. We almost finished the job on the same day. I'm very sorry that I didn't have the chance to take some pictures of the created parts after father went out to a factory to create two parts and came back to assemble with the suspension arm as I was away working on the other vehicle. When I came back to our garage, father told me to give a hand to install the whole left rear suspension arm to the vehicle. And father did the rest of the job and I went to work on the other vehicle. The following morning we pressured the hydrolastic system with coolant and bled the brake system. Father went out to take a test road and the angle seems right. Luckily I will have another chance to take some picture in the future. Father told me to do the right rear one one day. I have some other pictures I will show them up soon. Shipping heavy items to UK will cost me a lot. Regards Tony Tony, that's interesting. There is a reference in one of the LOCI magazines to a service that was/ is offered to replace these slipflex bearings with bronze or maybe brass I can't quite recall. But that would have required you to ship the arms back to the UK. If you have a chance I'm sure readers here would welcome more details of the teflon bearings and maybe a limited long term test? I guess I should have included rear suspension alignment in my earlier request for information as the slipflex can distort sufficiently for the rear tyre to touch the body and certainly upset the handling. Only Mk1 and rally cars used the roller bearings to my knowledge. Regards David |

|

|

|

Post by dave1800 on Oct 5, 2014 2:31:30 GMT

Hi Tony

Just a thought and I'm sure you and your father are many steps ahead of me anyway so this may be something others may wish to consider if they are replacing the rear arm bearings.

As you know,the Mk1 cars had conventional taper roller bearings in the front and rear suspension arms. You could push down the rear of the car without too much pressure and rock it up and down even though it would cease as soon as you stopped unlike a weak shock. On driving from a standing start the front of the car would rise noticeably and if you reverse and hit the brakes the rear actually rises several inches. Mk11/111 cars are very firm and damped in comparison and most of the characteristics I have described above are muted or almost absent. I imagine the change is primarily down to the suspension bearing changes.

Mk1 car also tend to brake flatter as the rear suspension pulls the back of the car down under moderate braking much more than on Mk11 cars and is almost totally absent on Mk111 vehicles.

If you were to use a Mk1 suspension on one side of the car and Mk11 on the other, I would guess given the characteristics that it could be unstable under braking. I cannot say for sure as I have no experience of it.

From your description I am not clear whether the modified rear suspension bearing using teflon is acting like the slipflex or more like a conventional bearing.

I think Tommy has a good description of the slipflex bearing operation somewhere, I will try and find it unless he gets there first!

regards

David

|

|

|

|

Post by tony on Oct 6, 2014 9:09:13 GMT

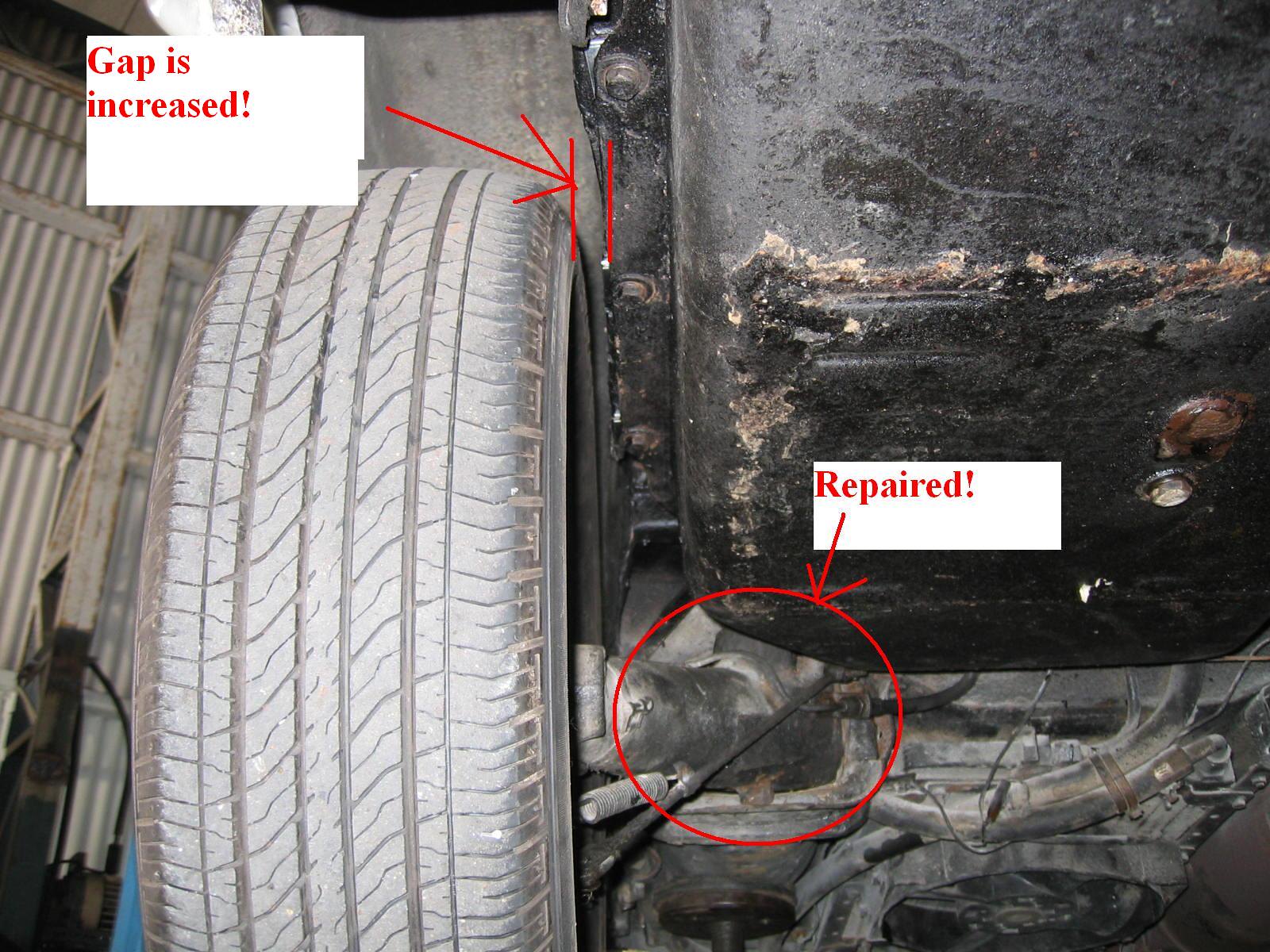

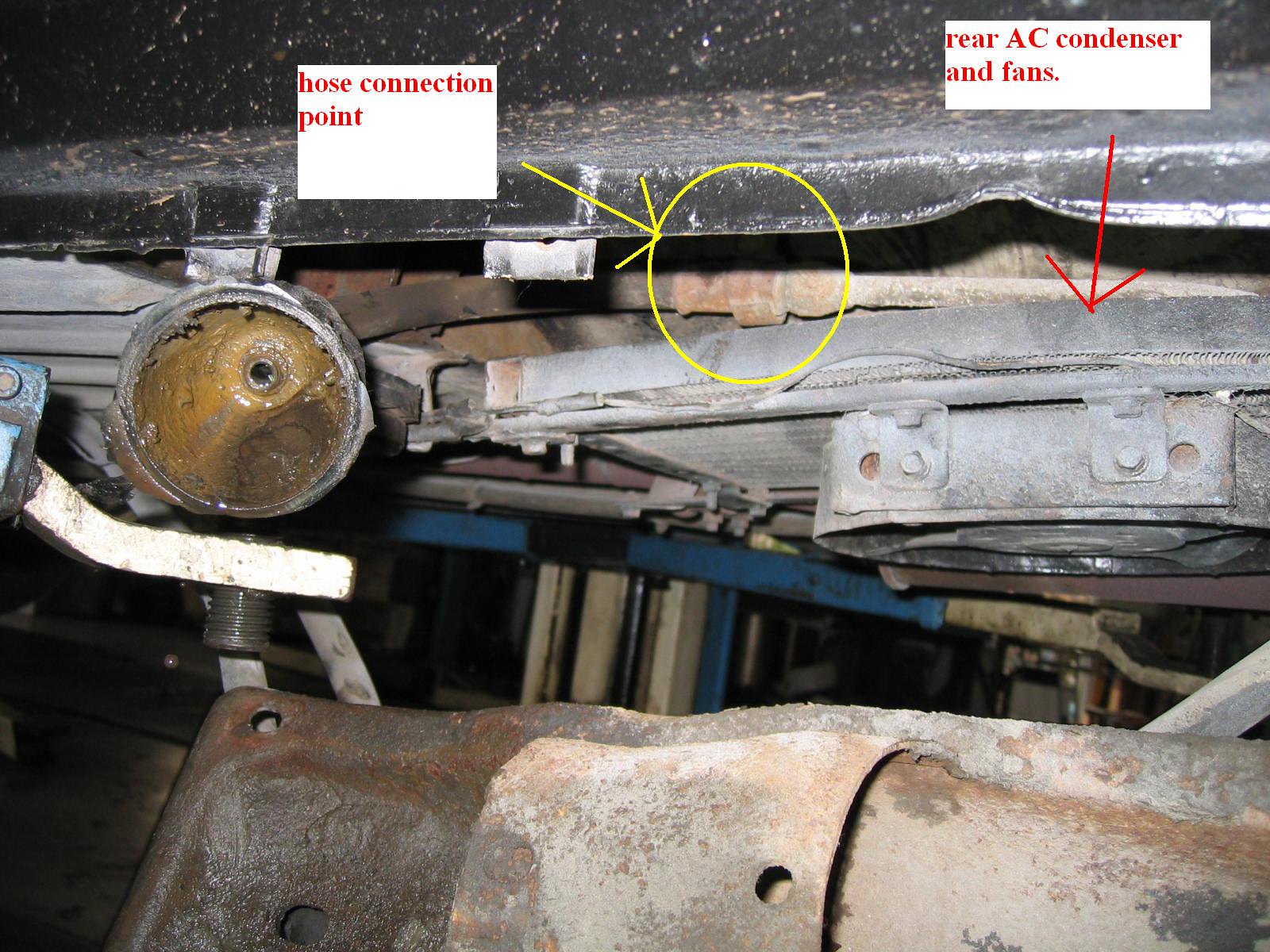

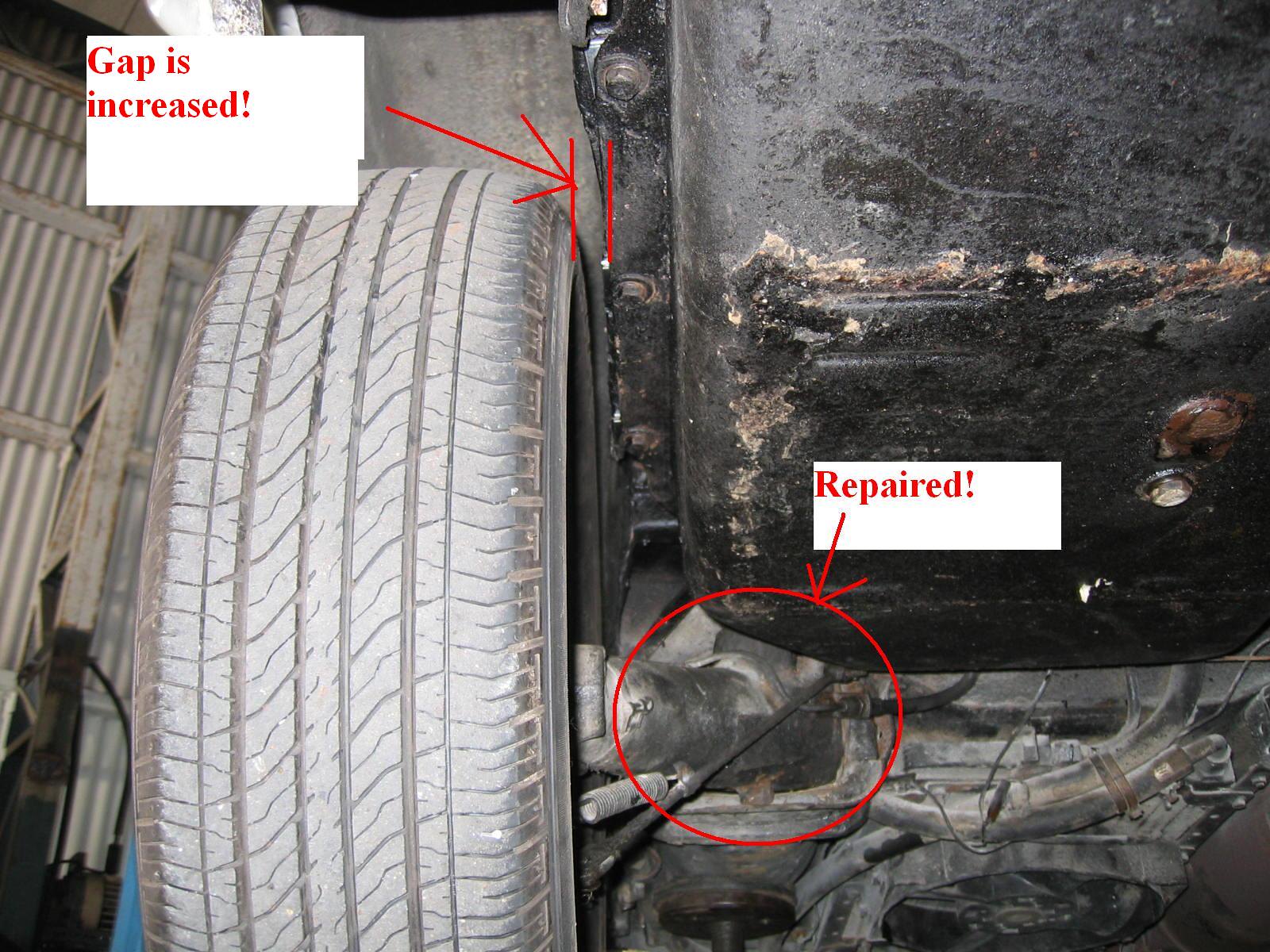

David Thank you so much for your description which I had never thought of before. I haven't met any MK-I and I don't think people here had imported any. I have seen 1100, 1300, 1500, 1750 and 1800 --- the one 1100 was brought to TAIWAN before the western car owner had to work here and took it with him. When he left for home and the 1100 was left here. As I have said before, we haven't done the same job for the rear suspension before. I'll try to notice if it works like the slipflex or more like a conventional bear. Actually we had this problem for many years and I have to say we didn't know how to deal with it. Parts are also one of the concerns. Father and I had noticed there was a loud and stranger click noise when driving on the uneven road. Now I realized that the cause is the worn out slipflex bearing and rubber on both side. Regards Tony  This is the left rear suspension arm we tried to repaired. Now there is a big gap between the tyre and the body. We also measure the gap with the vehicle on the ground --- more than a finger wide. When we tried to install the arm back to its housing of vehicle I noticed there was no gap left between the arm and the housing. We had to use hammers to slightly hit the arm to match the housing.  There is much less gap between the tyre and body of right rear suspension. We'll try to repair the problem one day. 24, August, 2017 added. The new rear right bushes were installed in July, 2017. The information will come soon.Hi Tony Just a thought and I'm sure you and your father are many steps ahead of me anyway so this may be something others may wish to consider if they are replacing the rear arm bearings. As you know,the Mk1 cars had conventional taper roller bearings in the front and rear suspension arms. You could push down the rear of the car without too much pressure and rock it up and down even though it would cease as soon as you stopped unlike a weak shock. On driving from a standing start the front of the car would rise noticeably and if you reverse and hit the brakes the rear actually rises several inches. Mk11/111 cars are very firm and damped in comparison and most of the characteristics I have described above are muted or almost absent. I imagine the change is primarily down to the suspension bearing changes. Mk1 car also tend to brake flatter as the rear suspension pulls the back of the car down under moderate braking much more than on Mk11 cars and is almost totally absent on Mk111 vehicles. If you were to use a Mk1 suspension on one side of the car and Mk11 on the other, I would guess given the characteristics that it could be unstable under braking. I cannot say for sure as I have no experience of it. From your description I am not clear whether the modified rear suspension bearing using teflon is acting like the slipflex or more like a conventional bearing. I think Tommy has a good description of the slipflex bearing operation somewhere, I will try and find it unless he gets there first! regards David |

|

|

|

Post by tony on Oct 10, 2014 1:44:46 GMT

Hi, everyone. I've discussed the headrests for the front seats with David. He suggests that I could post the pictures on the board and people who see these may benefit from my father's work and avoid a nasty injury. First of all, I received a parcel with three magazines from LOCI after joining it. I happened to see a picture of a 1800 which has got her headrests installed. In fact there are 2 1800s that have their headrests installed as far as I can find in the magazine. LOCI Magazine Winter 2013 Vol 24-4 the blue and white car on page 7 and the ute/panel van on page 8. David is not sure if the seats are not original. As of the rear end collision parents had in March, father has been thinking of how to install the headrests for the front seats since the Morris was repaired in August. We all know we don't have any the same material for the front seats. Father did try to search if there were two holes of the original front seats for installing headrests, but he didn't find any. He tried to do it in another way, perhaps it seems strange. But I know it does some help. Father went to a carbreaker to get a part for LS400 and he also asked for two second hand headrests. It seems he didn't find them right. A customer who knew gave us two kinds of headrests pairs. Then he bought a long metal water pipe and some others. He started to do what he had thought of the dream. This is what he has finished the job below.  Red arrows --- it used to be a LONG pipe between the two seats, father decided to cut it off.    |

|

|

|

Post by Penguin45 on Oct 10, 2014 8:30:22 GMT

Ingenius!

Chris.

|

|

|

|

Post by dave1800 on Oct 10, 2014 10:47:20 GMT

That's a clever solution. Maybe it would be good idea to cover the pipe with a tough polyurethane foam or similar as you can slide down in a seat after an impact and hitting the naked pipe with your neck would be very painful or worse.

regards

David

|

|

|

|

Post by tony on Oct 11, 2014 1:15:03 GMT

David You're right. It shall be covered. The disadvantage is that it's designed for ours, which means it cannot be adjustable and if someone is short, that can happen as you mentioned. Many thanks. Regards Tony  That's a clever solution. Maybe it would be good idea to cover the pipe with a tough polyurethane foam or similar as you can slide down in a seat after an impact and hitting the naked pipe with your neck would be very painful or worse. regards David |

|

|

|

Post by tony on Nov 13, 2014 8:41:25 GMT

A very serious problem came to us on the way to hospital yesterday afternoon. The left side of her fell down completely. Father managed to drive it back to our garage with a lot of attention of people on the road.    Managed to get the right lifting joints. |

|

|

|

Post by Penguin45 on Nov 13, 2014 12:50:42 GMT

Oh dear. Hopefully it's just a displacer hose which has failed. A hydraulic workshop should be able to renew it for you.

The car can be driven at 30 mph (About 50 kph) if the suspension collapses.

Good luck - look forward to the update.

Chris.

|

|

|

|

Post by tony on Nov 14, 2014 4:11:34 GMT

Hi! Chris Unfortunately we have a burst rear displacer unit. Regards Tony Oh dear. Hopefully it's just a displacer hose which has failed. A hydraulic workshop should be able to renew it for you. The car can be driven at 30 mph (About 50 kph) if the suspension collapses. Good luck - look forward to the update. Chris. |

|

|

|

Post by tony on Nov 15, 2014 4:52:14 GMT

|

|

|

|

Post by tommydp on Nov 15, 2014 9:37:06 GMT

Hi Tony!

Sorry to learn about your displacer failure, nothing more annoying than that sinking hydrolastic sight..

On the bright side, the rear one is easiest to replace. Too bad, as you just had it off to fix the slipflex bearing. I suppose it's just bad luck, or do you have any indication the bearing work/replacement contributed to the failure? By all means, you and your father's skills seems extremely high and well above mine, but it could be of interest to other enthusiasts, if there are issues to steer away from when working on the bearings.

I hope you have a replacement displacer, if not Tony W will have one I guess.

Tommy

|

|

|

|

Post by Penguin45 on Nov 15, 2014 10:03:48 GMT

Very unlucky, Tony. Interesting to see how much muck has collected inside the displacer over the years.

Chris.

|

|

|

|

Post by dave1800 on Nov 16, 2014 2:00:26 GMT

Perhaps the fluid should be changed every few years as the anti rust properties deteriorate? Thoughts anyone? Very unlucky, Tony. Interesting to see how much muck has collected inside the displacer over the years. Chris. |

|